Dr. Marsha Dickson, President and Co-Founder of Better Buying Institute on how, when it comes to defining standards for purchasing practices, ‘responsible’ will look different for different companies

Purchasing practices have become a top priority for the fashion industry, as understanding grows among brands and retailers of the myriad of practices that negatively impact suppliers, workers, and the environment.

As every new business need emerges, so too do organizations seeking to find solutions to those needs, and the race is on to contribute solutions and set standards for what responsible purchasing practices look like.

Better BuyingTM supports supplier-led efforts to identify the level of performance they need from their customers in order to operate financially, socially, and environmentally sustainable businesses. The Sustainable Terms of Trade Initiative set out the minimum standards of commercial compliance suppliers expect to see in its 2021 White Paper. But of course, minimum standards won’t be enough to achieve important goals like Living Wages and Net Zero. Where then should the bar be set for what are truly best practices that will support sustainability strategy?

When it comes to best practice, from my focus on the topic of purchasing practices for 20 years, and access to all the data from suppliers that Better BuyingTM has gathered in the seven years since its inception, it is clear that a ‘one size fits all’ set of standards applicable to every company to pursue as best practices cannot be developed.

Responsible purchasing practices for brands and retailers depend on many things: the products they sell; their business models; and other variables. Even within one company, purchasing practices that are responsible could vary from one unit to another.

Take, for example, an athletic brand selling high tech products with long R&D cycles requiring close collaboration with suppliers, and factories devoting all their capacity to the brand to prevent IP disclosures to competitors. This brand will likely need to be forecasting at least a year out so that special materials can be manufactured, and working with suppliers to level load production and delivery since suppliers can’t fill in their capacity with other brands’ orders.

Now let’s consider a cost-conscious, fast fashion retailer selling poly cotton tees. They might be fine forecasting just 90 days out since the raw materials should be easier to source or kept on hand as greige since many customers will use similar materials. Suppliers will almost always be working with several customers to utilize factory capacity, although they’ll still need enough time to plan their production without requiring excessive overtime. For this retailer, costing and payment practices might need to be the top concern since they will often be working with undercapitalized manufacturers desperately trying to manage cash flow and pay for raw materials and worker wages. Responsible purchasing practices may require deposits when orders are placed, more flexibility in delivery dates so that excessive overtime is avoided, and multi-year commitments so suppliers can secure materials at the very best cost.

With all this variability, how can we determine whether brands and retailers are paying attention to the right issues—and making improvements that will result in purchasing practices that are responsible for their businesses and supply chains?

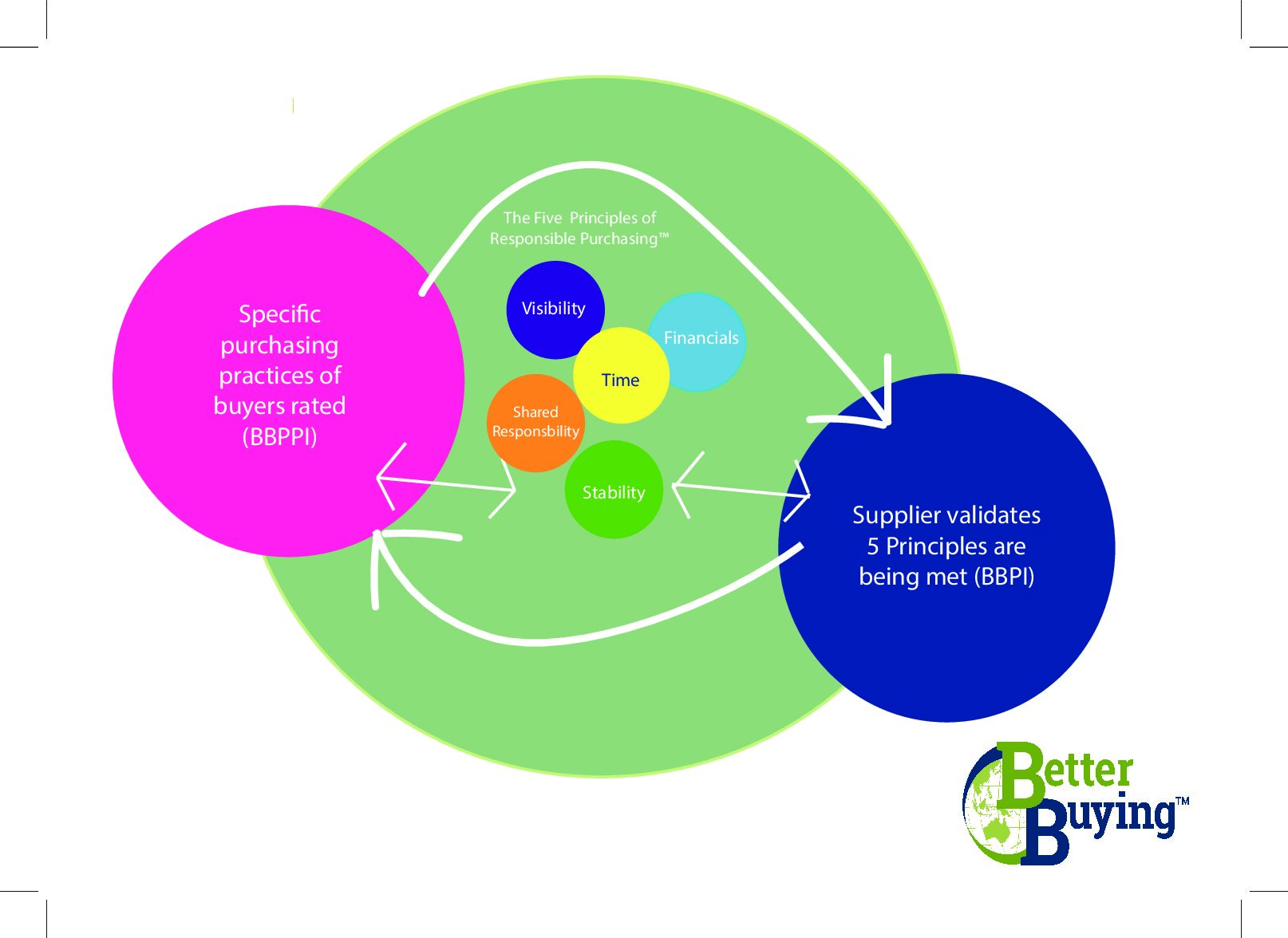

Better Buying Institute has defined Five Principles of Responsible PurchasingTM that, when combined with data gathered in our Better Buying Purchasing Practices IndexTM (BBPPI) and Better Buying Partnership IndexTM (BBPI), can guide brands and retailers to where they need to end up, with their forecasting, their costing, and other practices.s

Thinking back to the companies described earlier, each can track exactly where their practices fall on a continuum, from terrible to ideal, using our BBPPI. They’ll see how they compare with others in the industry and can start to shore up areas of poor performance and track those improvements over time. But how far do they need to go? And when will they have good enough purchasing practices?

Our Five Principles guide brands and retailers to give enough visibility to suppliers about planned business; provide enough stability in the form of steady and predictable business across the year; give suppliers enough time to complete all processes; use fair financials; and share responsibility with suppliers for improving supply chain social and environmental sustainability.

What constitutes “enough” needs to be determined by each individual company’s suppliers, which is where our BBPI comes into play. This is the survey that asks suppliers to simply indicate whether they have enough visibility, whether they believe the financial arrangements are fair, and other purchasing practices aligned with the details of the BBPPI and the broad guidance of the Five Principles. If you are a brand or retailer and all of your suppliers are scoring you in the green zone on these BBPI questions, you will have found what’s responsible and will be a True Partner to your suppliers.

Utilizing these principles and data ensures that brands and retailers aren’t held to irrelevantly high standards, or get by despite underperforming to their supply chains’ needs.

For everyone interested in defining standards for purchasing practices, let’s first of all recognize that ‘responsible’ will look different for different companies. One company’s business is very different from another’s, and the best we can do is to point them down the right path, and let their suppliers confirm when they’ve arrived at the right destination.